Welcome, Guest. Please login or register.

Did you miss your activation email?

Show Posts

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Pages: [1]

1

General Outdoor Furnace Discussion / Need suggestions

« on: November 27, 2016, 06:43:56 PM »

I built my OWB in 2014 (can see the build if you search under homemade and look for post under my userID). I have used it for the past two winters, and have fired it up for this season already. I am at my wits end trying to figure out my wood consumption. The OWB heats the house and DHW fine, but it seems like I am going through ridiculous amounts of wood to do it. Here's my setup: Approximately 175' of 1" pex-al-pex to the middle of the crawlspace where it transitions to 1" regular pex, goes to the 30 plate at the water heater, then to my coil, then back to the crawlspace where it transitions back to 1" pex-al-pex to head back to the boiler. Total round trip is approximately 400'. I spray foamed it in the trench. I'm wondering if this is my problem? I noticed last year that there was SOME snow melt by my boiler and near where the pipe enters the house, but I didn't think it was TOO significant. Pipe averages about 30" deep for the majority of the trip through the yard. My Maverick temp indications show 7 degrees difference round trip when nothing is calling for heat. Both are strapped to the piping at the boiler (supply and return). I don't have any in-line temp gauges. I'm heating 1800 sf of decently insulated home (built in '04) and DHW. We use a lot of hot water, and for some reason our incoming water line is extremely cold in the winter time. I have seen it pull the return temp down 40 degrees when we are running both showers. If the heat kicks on, it will drop it a little more. This tells me I am not moving the water fast enough, but I figured a TACO 0013 would have been enough when I did my initial head loss calculations. Things I have tried: adjusting amount of air flow, adding fire brick to bottom of firebox, using seasoned wood only, using green wood only, using a mix of wood, thrown in a little coal, played with increasing and decreasing my differential setpoints for when the blower kicks on and off (currently set at 12 differential--168 on, 180 off.) Nothing has made an appreciable change in wood consumption. I also placed a scrap piece of 1/4" steel in front of the chimney in the firebox so the flames won't blow up the stack. Instead, they hit the plate, roll up and around the tank, then go down and exhaust up the stack to conserve some of the heat.

When I load the furnace, in milder weather like now (typically upper 30s and lower 40s) I can fill it 2/3 full and it will last 11-12 hours. Last night it dropped to upper 20s. I loaded it 2/3 full at 7:30 and at 3:45 am my alarm was going off for low temp (out of wood). There was a heavy frost on the ground this morning, but none of it was melted over the lines. To get an idea of how much I am loading, I am putting about 10 pieces in, approximately 18-24" in length and anywhere from large splits to whole 6" round un-split logs. When it gets to teens and especially single digits, I can fill this thing up full and get 8 hours of it. My back can't take this much longer! A rick (4x8 face cord) lasts me about 3 to 3 1/2 days in the middle of winter.

Is my furnace undersized? Are my lines junk? What am I doing wrong?

When I load the furnace, in milder weather like now (typically upper 30s and lower 40s) I can fill it 2/3 full and it will last 11-12 hours. Last night it dropped to upper 20s. I loaded it 2/3 full at 7:30 and at 3:45 am my alarm was going off for low temp (out of wood). There was a heavy frost on the ground this morning, but none of it was melted over the lines. To get an idea of how much I am loading, I am putting about 10 pieces in, approximately 18-24" in length and anywhere from large splits to whole 6" round un-split logs. When it gets to teens and especially single digits, I can fill this thing up full and get 8 hours of it. My back can't take this much longer! A rick (4x8 face cord) lasts me about 3 to 3 1/2 days in the middle of winter.

Is my furnace undersized? Are my lines junk? What am I doing wrong?

2

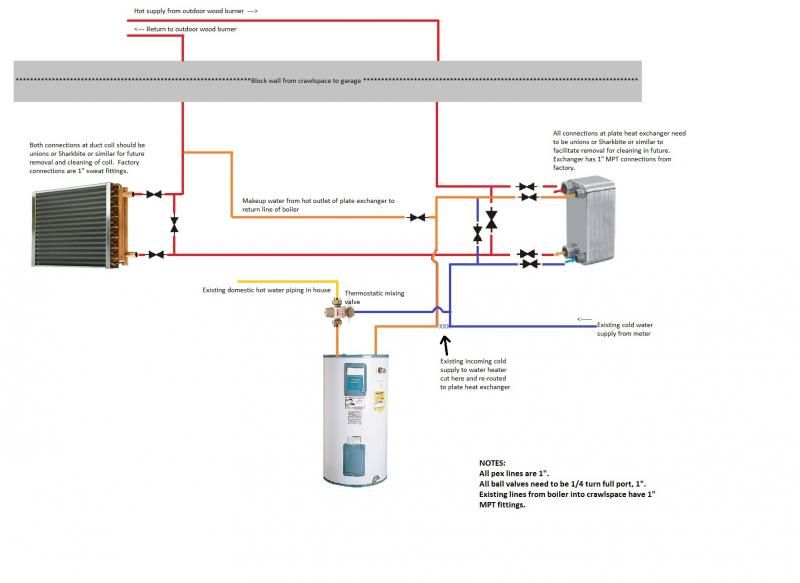

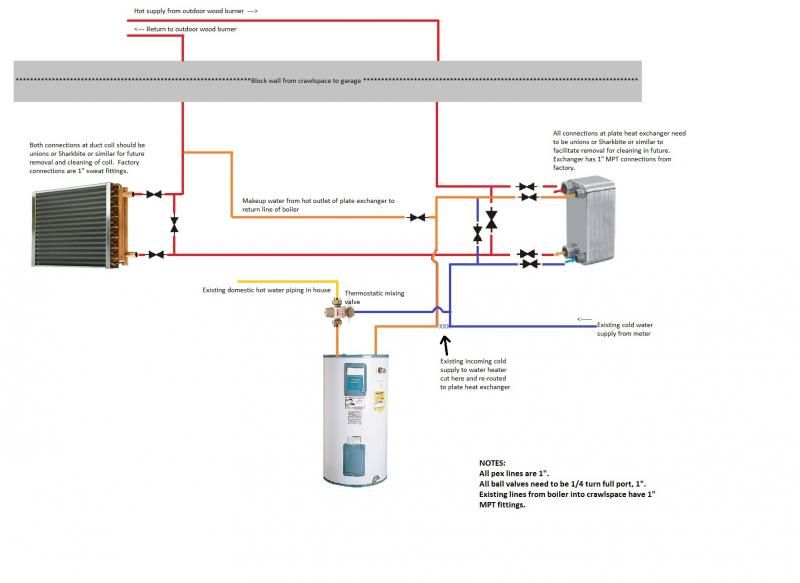

Plumbing / Plumbing schematic

« on: November 10, 2014, 02:59:40 PM »

I had a local plumber come out to look at making all the connections (I hate plumbing, and can't justify buying the crimp tools to complete just one job.) He said he understood what I was wanting to do, but was going to have difficulty explaining it to his employees, so I said I would throw together a rudimentary drawing showing the flowpath. I told him that although it looks like a bunch of 90's in it, there really weren't, I was just trying to fit everything onto a page. Does this drawing appear to be an adequate representation? I am running both heat exchangers in series with individual isolation valves and by-passes around both heat exchangers, a thermostatic mixing valve on the outlet of the water heater and a boiler fill/make-up water line tying into the return to the boiler coming from the hot outlet of the plate heat exchanger. Am I missing anything important?

3

Home Made / Insurance woes

« on: April 28, 2014, 04:16:25 PM »

Anybody else have any issues with their insurance carrier over a home made wood burner? Mine says no-go and that they will not cover mine due to not being UL listed and something about NFPA 211 compliance, although NFPA 211 appears to have to do with indoor wood appliances, minimum offsets, insulation of chimney, etc. I have KY Farm Bureau for my carrier. Just curious who everyone else uses and their insurer's policy on home made wood burners.

4

General Outdoor Furnace Discussion / Major insurance hurdle

« on: April 28, 2014, 04:03:07 PM »

Talked to the insurance agent over the last few days regarding my build. He contacted the underwriter, who said no way they would cover a home-made wood stove. He kept cited UL listing and NFPA211 compliance to underwrite. I kept trying to explain that it was not in the house, but out in the field behind the house, but I guess the underwriter is too deaf/dumb to understand the difference between a wood stove IN a house and an outdoor wood furnace AKA hydronic heater sitting 100 feet from the house. I couldn't find anything in NFPA 211 that referenced outdoor wood burners, but I realize he's already set in his decision. I also noted that it was not the primary, but a supplemental source of heat once it was finished. The conversation ended with me letting them know that once I get it finished, I would be switching insurance companies to one that wants my business. Personally, I think it's ridiculous. I could understand if it was some hack-job that somebody was trying to put in their living room, but an outdoor wood furnace? Gimme a break. Just a head's up for any of you who may be building or planning to build one and currently have Kentucky Farm Bureau insurance for your carrier.

5

Home Made / Need help with boiler door design

« on: March 20, 2014, 11:13:06 AM »

Anybody have any drawings of how they built their door? Been thinking about this a lot lately. Can't decide if I want the blower mounted on the door, or if I want to torch out an opening and pipe the air in under the door to prevent the fan from being exposed to heat. Pictures, drawings or suggestions on how-to are appreciated. I already have the pipe if I decide to locate the fan in a box away from the door, so that is a possibility and is the direction I am leaning in. Thanks!

6

Home Made / Determining heat load and sizing of pex??

« on: February 11, 2014, 11:28:30 AM »

I'm still in the planning phases of my build (mostly due to weather not cooperating with my off days from work!) but I am having trouble figuring out how to calculate my heat load. I've seen rough estimates of 40 btu per sq foot for my area of the country (western KY), but I have no idea what I need for the domestic hot water. I know the BTU ratings of the heat exchangers are the max output of that particular exchanger per hour, but how do I know what I need exactly? My house is 1800 sq feet, fairly well insulated (built in 2004) and I plan to run the plate heat exchanger for domestic water heater in series first, then to the heat exchanger in the ductwork, then return to boiler. The water heater is 82 gallons. I was thinking about using 1” pex for the whole loop (roughly 130 feet each way with a TACO 0015 3 speed), until I saw that 1” pex is only good for about 7.5 GPM, which would likely be about 75,000 BTU per hour, if what I read was accurate. I’m not sure that would be enough. Should I opt for 1” pex-al-pex or Logstor to get higher GPM or am I over-estimating what I will actually be seeing for heat load? Some help or direction with accurately calculating my heat load would be really appreciated. Thanks in advance.

7

Home Made / New build plan, looking for suggestions

« on: January 09, 2014, 11:35:12 AM »

I've been reading for a week or so, and I appreciate all the free knowledge available on this site. Looking for comments, concerns, questions, and suggestions to improve my plan. I am planning to build an outdoor wood boiler, relying heavily on my father-in-law who is a retired welder/fabricator with over 40 years of experience, which is a good thing considering I hardly know how to turn my mig welder on, much less use it to weld watertight. Here’s the plan: I have a 300 gallon diesel fuel farm tank that I have had for years that I plan to use as the water jacket (hasn't had fuel in it in over a decade). It’s relatively thin metal (probably 1/8”?) but if it’s designed to hold fuel, I figure it would make an OK water jacket. It measures 38” in diameter and is 60” long. I plan to have a piece of 3/16 steel rolled into a 24” cylinder for the firebox. Not sure on how long to go. I don’t want it to go completely the whole 60” length of the tank, so I’m not sure if I should use a rear exit flue or a top exit. I will have the blower with damper controlled via either aquastat or ranco controller, not sure which I plan to use yet, so I’m open to any suggestions. I would like to install an ash pan in the bottom of the box with some grating, but cannot figure out how I want to build the door or where I can buy a pre-made door. Also, I would like to put the air in from the back side of the firebox rather than at the door if possible, but that would likely mean I would have to run the firebox the full length of the water jacket, so I’m still pondering how to do this. I am planning on buying pre-made insulated pex, so I am trying to make this work with only 1 pair of 1” lines due to cost (rough estimate of about 130-150 feet of run, depending on my exact location of the boiler). My plans are to have a 20-plate 5X12” brazed plate heat exchanger on the water heater (82 gallon electric water heater) first in the circuit, then to the air/water heat exchanger in the ductwork, then returning to the boiler. I also plan to put a “T” in the return line to the boiler and tie into my domestic water supply via a ¼ turn valve for a means to top off the boiler without having to stretch out a garden hose. I’m thinking I should come off the hot water side of the water heater to keep from shocking the boiler so much with cold water during top offs. I do plan to install a thermostatically controlled anti-scald valve to the water heater to prevent kids from getting burned by the hot water in the house. My current setup has a heat pump with 15kw backup electric strips, which have proven to be very costly, not to mention the dual 4500 watt elements in the water heater eating $$$, especially in the winter time. The house is 1800 sq ft of living space, and is fairly well insulated (built in 2003). Since my heat pump has a variable speed blower, from what I have read, I should be able to utilize a second aquastat surface-mounted on my supply line from my boiler and have it hold the contacts open on my yellow wire to my outside unit on the heat pump unless the boiler water temp falls below say 120 degrees (indicating fire went out) whereby it would then close the contacts to allow the heat pump to run normally and allow the backup heat strips to function as normal, and I would be able to continue just using my normal thermostat. Otherwise, I would run into issues of the blower not wanting to spin up to high speed. Since I’m only planning on one set of lines from the boiler for heat and hot water, I would just run my circulator 24/7 as many people do, and I’ve heard that the circulators seem to hold up pretty well like this and don’t use a whole lot of electricity anyway (about similar to a 100 watt bulb). I am open to any and all suggestions, and I have looked at a number of different builds on this site and continue to be impressed with everyone’s ingenuity and the amount of thought and design that go into these builds. I've run various calculations on the size of the firebox, determining how many gallons would be left for the water jacket, etc., just not sure how much of each is enough or too much. Looking forward to some good advice! Thanks in advance.

Pages: [1]