Welcome, Guest. Please login or register.

Did you miss your activation email?

Show Posts

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Pages: [1] 2

1

Home Made / Re: Higher efficiency conventional build scotch type

« on: September 14, 2016, 08:52:26 AM »

One last update on this project, for me anyways.

We have sold the farm so perhaps the new owner will post!

Over the summer the only thing I changed was the blower/damper setup. I didn't like the damper flap on the outside of the blower because when the boiler idles, the smoke can condense into creosote on the blades of the blower and blower internals.

So I've put a damper flap between the blower and the air intake. Also, I can adjust the amount of air that goes into the primary or secondary air intake by raising or lowering the damper/blower setup on the flange.

Sorry for the blurry pics, my phone doesn't have a great camera!

I'll still check back on here once and a while too, this won't be my last boiler!

In Liberty

Ben

We have sold the farm so perhaps the new owner will post!

Over the summer the only thing I changed was the blower/damper setup. I didn't like the damper flap on the outside of the blower because when the boiler idles, the smoke can condense into creosote on the blades of the blower and blower internals.

So I've put a damper flap between the blower and the air intake. Also, I can adjust the amount of air that goes into the primary or secondary air intake by raising or lowering the damper/blower setup on the flange.

Sorry for the blurry pics, my phone doesn't have a great camera!

I'll still check back on here once and a while too, this won't be my last boiler!

In Liberty

Ben

2

Advanced Electronics / Re: Electricity

« on: May 16, 2016, 09:56:08 AM »

You could use peltier junctions. Especially if you used it in the winter, because they work best with a large temperature differential. That's what's in those little stove top fans that run off the heat of the stove. Hardly make any power though.

Ben

Ben

3

General Discussion / My Vote (short article)

« on: March 02, 2016, 07:31:43 AM »

My Vote

By Brian Wilson

March 2, 2016

Maybe if I post it here, the phone will stop ringing, the mailbox will unclog and everyone who really really wants to know will….know.

Actually, I’m really excited about my guy! Can’t say I’ve ever been this stoked about a candidate! How could anyone not be?

Unlike Trump, he has definitive, articulate plans for the future;

Unlike Rubio, he has no checkered “Gang of 8” or other skeletons in his closet;

Unlike Cruz, he has never flip-flopped on essential issues of Freedom nor does his wife work for Goldman-Sachs;

Unlike Dr. Carson, he has zero surgical skills but does posses a dynamic personality and excellent speaking skills;

Unlike Kasich, my guy has a brain, respect for the individual and eschews making Judo hand gestures when speaking; my guy’s father was not a mailman.

The person I’m voting for has always been courteous and responsive to my queries and honestly concerned about my concerns for the future and my family;

He has demonstrated fiscal responsibility, the financial discipline to run clean, efficient businesses; he respects the entrepreneur and importance of the Small Business Owner;

He agrees with me: taxation is theft;

He understands the vicissitudes of “politics”, career politicians and the Siren song of Power;

Just like me, he believes strongly in the sanctity of Life, Liberty and the pursuit of Happiness, the primacy of the Individual, free markets, Natural Law and Spontaneous Order;

He agrees and believes “the Individual is the smallest minority on earth”;

Unlike Kasich and others, my guy understands “Individual rights are not subject to a public vote”;

He often quotes Henry David Thoreau: “I wasn’t born to be forced.”

He unequivocally supports Self-Governance.

And, yes, he is the “Boss of Me” — and I’m totally OK with that!

That’s why, again this election, I am throwing my entire support and vote for the only person who knows what’s best for me, born to be the only “Boss of Me:

Me.

*copied from: https://www.lewrockwell.com/2016/03/brian-wilson/vote-3/

In Liberty

Ben

By Brian Wilson

March 2, 2016

Maybe if I post it here, the phone will stop ringing, the mailbox will unclog and everyone who really really wants to know will….know.

Actually, I’m really excited about my guy! Can’t say I’ve ever been this stoked about a candidate! How could anyone not be?

Unlike Trump, he has definitive, articulate plans for the future;

Unlike Rubio, he has no checkered “Gang of 8” or other skeletons in his closet;

Unlike Cruz, he has never flip-flopped on essential issues of Freedom nor does his wife work for Goldman-Sachs;

Unlike Dr. Carson, he has zero surgical skills but does posses a dynamic personality and excellent speaking skills;

Unlike Kasich, my guy has a brain, respect for the individual and eschews making Judo hand gestures when speaking; my guy’s father was not a mailman.

The person I’m voting for has always been courteous and responsive to my queries and honestly concerned about my concerns for the future and my family;

He has demonstrated fiscal responsibility, the financial discipline to run clean, efficient businesses; he respects the entrepreneur and importance of the Small Business Owner;

He agrees with me: taxation is theft;

He understands the vicissitudes of “politics”, career politicians and the Siren song of Power;

Just like me, he believes strongly in the sanctity of Life, Liberty and the pursuit of Happiness, the primacy of the Individual, free markets, Natural Law and Spontaneous Order;

He agrees and believes “the Individual is the smallest minority on earth”;

Unlike Kasich and others, my guy understands “Individual rights are not subject to a public vote”;

He often quotes Henry David Thoreau: “I wasn’t born to be forced.”

He unequivocally supports Self-Governance.

And, yes, he is the “Boss of Me” — and I’m totally OK with that!

That’s why, again this election, I am throwing my entire support and vote for the only person who knows what’s best for me, born to be the only “Boss of Me:

Me.

*copied from: https://www.lewrockwell.com/2016/03/brian-wilson/vote-3/

In Liberty

Ben

4

General Outdoor Furnace Discussion / Re: Temp display in the house

« on: February 22, 2016, 08:46:01 AM »

I use the maverick too, I have one probe on the water jacket and one in the stack. That way I can tell where its at in its cycle also. And you can tell if its out of wood or if she needs a cleanin'.

I had to clip the wire going to the beeper. I must be almost out of range for it because at night sometimes it would lose signal and wake us up. It generally finds signal again in an hour by itself though.

In Liberty!

Ben

I had to clip the wire going to the beeper. I must be almost out of range for it because at night sometimes it would lose signal and wake us up. It generally finds signal again in an hour by itself though.

In Liberty!

Ben

5

Home Made / Re: Higher efficiency conventional build scotch type

« on: February 04, 2016, 11:53:31 AM »

Just a quick update!

I think I'm completely tuned in now (until the summer shutdown!) It's been running good. I've changed from a fan to a blower and rearranged my damper setup because of backfiring upon loading a big load of wood scraps on hot coals and the woodgas igniting and backfiring through my fan. I've added a one way blast flap on the intake tract. I clean the flues about every 3 weeks or a month it seems.

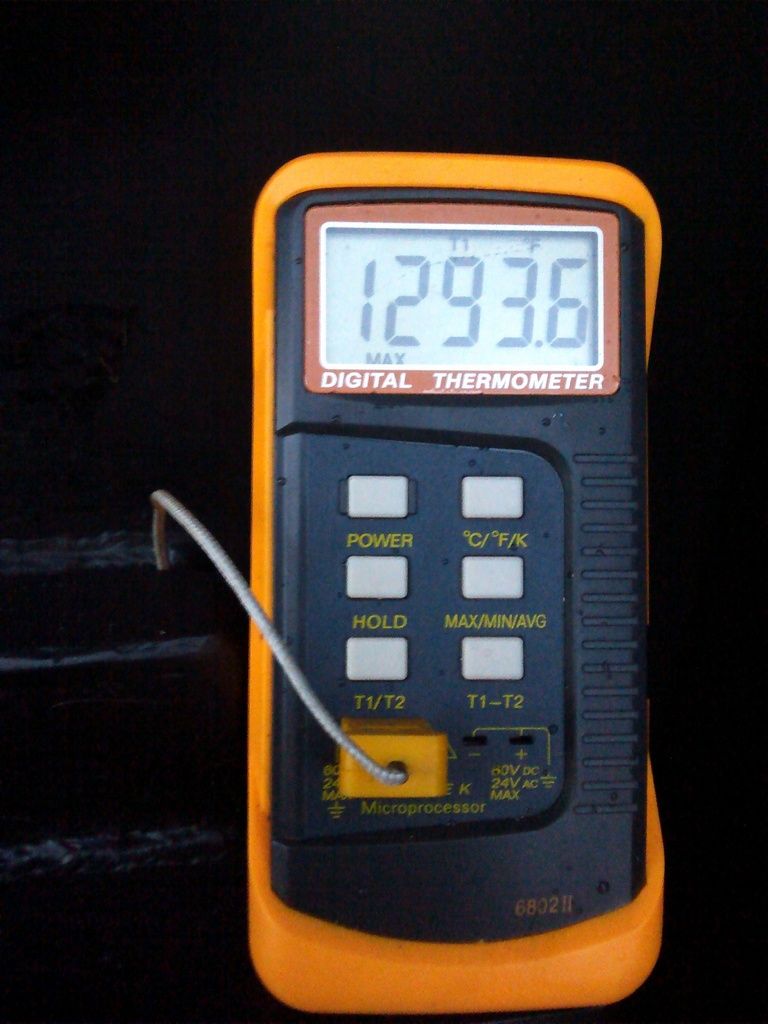

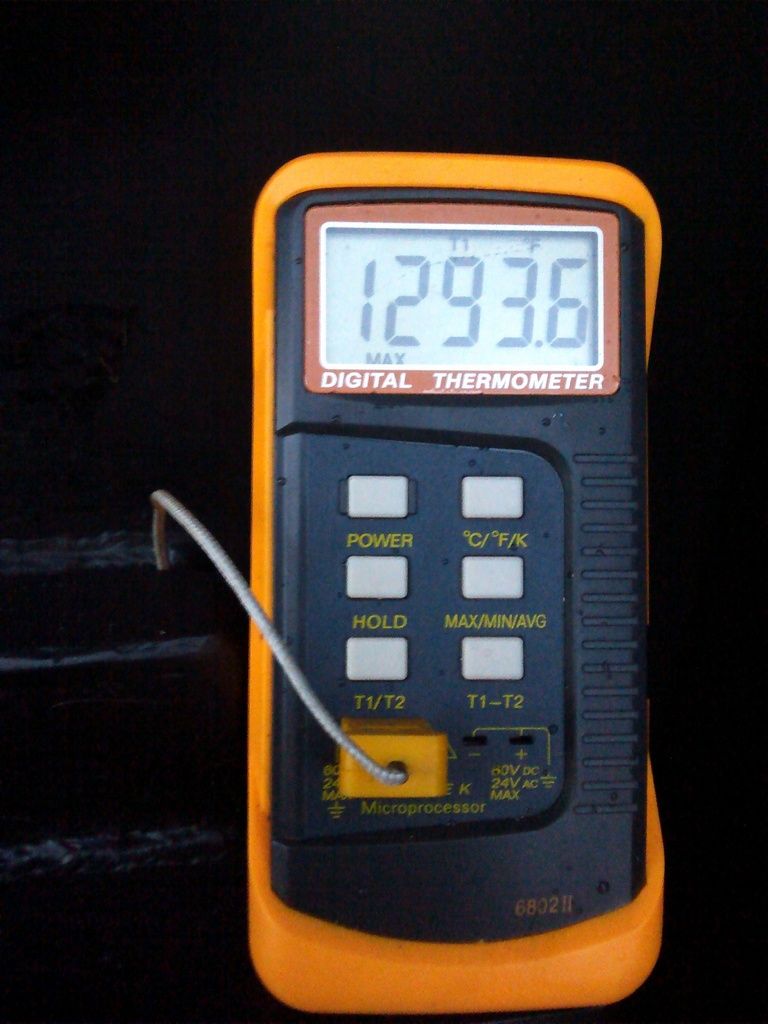

These are my temps in the to top the firebox now:

I took a video, you can see the flames curling around in the top by the baffle plates. It pretty much always has the wispy flames dancing up there but with the door closed and only open a very tiny crack there is a flamethrower blasting upward from the air injection at the front of the firebox. That disappears when the door is opened wide.

hope that video works!

I will take some pictures next clean out.

In Liberty!

Ben

I think I'm completely tuned in now (until the summer shutdown!) It's been running good. I've changed from a fan to a blower and rearranged my damper setup because of backfiring upon loading a big load of wood scraps on hot coals and the woodgas igniting and backfiring through my fan. I've added a one way blast flap on the intake tract. I clean the flues about every 3 weeks or a month it seems.

These are my temps in the to top the firebox now:

I took a video, you can see the flames curling around in the top by the baffle plates. It pretty much always has the wispy flames dancing up there but with the door closed and only open a very tiny crack there is a flamethrower blasting upward from the air injection at the front of the firebox. That disappears when the door is opened wide.

hope that video works!

I will take some pictures next clean out.

In Liberty!

Ben

6

Home Made / Re: Higher efficiency conventional build scotch type

« on: December 10, 2015, 06:36:21 AM »

Hey, that little window looks good! Did you use the special temperature glass? I would have to take my door off and bore a hole through it and then add a tube of some sort through the insulation, similar to yours it looks like. The down draft gasser sure does blow some fire down there! It's nice to watch it with the door closed so you know your not affecting the burn when you open the door!

Maybe a window is a job for the spring shutdown for me.

Thanks for posting that!

In Liberty

Ben

Maybe a window is a job for the spring shutdown for me.

Thanks for posting that!

In Liberty

Ben

7

Home Made / Re: Higher efficiency conventional build scotch type

« on: December 09, 2015, 09:50:03 AM »

Well, I'm a tinkerer and can't quite leave anything alone.

I've been playing with the air speed control to tune the firebox temp and secondary combustion quality. I was getting temps in the 1300-1450 range but it seemed somewhat sporadic , It depended on how much wood was loaded and how many cycles after the wood was loaded. It seemed to smoke more and have lower temps when fresh wood went in.

It was my suspicion I didn’t have enough secondary combustion air. So first I added an adjustable plate in the blower stream to block off some of the underfire air and therefore push more to the gasification tube. Things were better. I reduced the fan speed which made the fire less roaring but more of the smoke was burned off. The primary fire would have been creating less volatile gases. Still about the same temps but a little less smoke out the stack.

Then I added a second gasification tube underneath the first. I made it out of some 2x3” tube I had laying around. I figured I had to much friction loss on the gasification tube to get that quantity of air above the fire. This helped too but was still sporadic.

I thought I still needed more air… So My under fire air comes in from the back and over the ash pan and up slots that are about 1.75x5” in the bottom V of the firebox. There was 3 of them, The one at the very front was kind of hard to poke ash through because its fairly low right inside the door. So overtop of this air hole I bolted in a piece of 3x5 tube with a ramp to cover up the whole air slot. (if that makes sense, I will take pics soon). On top of the tube I welded a plate that ramps toward the firebox baffle plates and has 2 big slots in it to blow air directly towards the original gasification tube. The big tube is about 16” long and stops flush with the bottom door flange. I then took out the divider plate and turned the fan back to high.

This made a drastic difference. When I stoked the fire this time my thermocouple probe jumped to 1400, then 1650 then 1875 and then went blank… It has melted/broke my probe. When I cracked the door the flames shooting off of the air intake tube in the front of the firebox looked like a torch. The flames started about 4” away from where the air was injected and was swirling around the curves on the baffle plate. I have been through both of my probes and have a new stainless steel higher temperature one on the way.

All of these changes have been made with the boiler still making usable heat so I’ve been letting it burn out and do the change and start a new fire all before the water temp goes below about 150. My next step is to sawzall/grind off the new rectangle gasification tube all the way back to where it makes its 90 bend in the top of the firebox. This will get more flow back there.

So by now I have figured out a few things I would change if I did it all again. First I had to put on a rain cap with a small mesh spark arrestor. That thing gummed up fast and dripped creosote all over the roof. It seemed to gum up when I was tinkering and burning much less smoke and just after the fan kicked on but before burning the smoke. I would also move my water level indicator. It is a high temp silicon tube in a nice, easy to see spot but got dirty from smoke out the door pretty quick, you need to wipe it off to see the water level. And If starting over I would make the original gasification tube much larger for flow or have a second fan that could be controlled independently for maximum efficiency. The original one was certainly better than nothing but it was improved greatly after modification. The baffle plates seem to work good, I would maybe extend them a little bit lower on the outside edges. But that would take away some firebox space.

I’m going to try and get a video of the secondary combustion. It sure is hard though with no viewing window!

I hope this might be helpful to someone planning a build or wanting to modify theirs!

In Liberty

Ben

I've been playing with the air speed control to tune the firebox temp and secondary combustion quality. I was getting temps in the 1300-1450 range but it seemed somewhat sporadic , It depended on how much wood was loaded and how many cycles after the wood was loaded. It seemed to smoke more and have lower temps when fresh wood went in.

It was my suspicion I didn’t have enough secondary combustion air. So first I added an adjustable plate in the blower stream to block off some of the underfire air and therefore push more to the gasification tube. Things were better. I reduced the fan speed which made the fire less roaring but more of the smoke was burned off. The primary fire would have been creating less volatile gases. Still about the same temps but a little less smoke out the stack.

Then I added a second gasification tube underneath the first. I made it out of some 2x3” tube I had laying around. I figured I had to much friction loss on the gasification tube to get that quantity of air above the fire. This helped too but was still sporadic.

I thought I still needed more air… So My under fire air comes in from the back and over the ash pan and up slots that are about 1.75x5” in the bottom V of the firebox. There was 3 of them, The one at the very front was kind of hard to poke ash through because its fairly low right inside the door. So overtop of this air hole I bolted in a piece of 3x5 tube with a ramp to cover up the whole air slot. (if that makes sense, I will take pics soon). On top of the tube I welded a plate that ramps toward the firebox baffle plates and has 2 big slots in it to blow air directly towards the original gasification tube. The big tube is about 16” long and stops flush with the bottom door flange. I then took out the divider plate and turned the fan back to high.

This made a drastic difference. When I stoked the fire this time my thermocouple probe jumped to 1400, then 1650 then 1875 and then went blank… It has melted/broke my probe. When I cracked the door the flames shooting off of the air intake tube in the front of the firebox looked like a torch. The flames started about 4” away from where the air was injected and was swirling around the curves on the baffle plate. I have been through both of my probes and have a new stainless steel higher temperature one on the way.

All of these changes have been made with the boiler still making usable heat so I’ve been letting it burn out and do the change and start a new fire all before the water temp goes below about 150. My next step is to sawzall/grind off the new rectangle gasification tube all the way back to where it makes its 90 bend in the top of the firebox. This will get more flow back there.

So by now I have figured out a few things I would change if I did it all again. First I had to put on a rain cap with a small mesh spark arrestor. That thing gummed up fast and dripped creosote all over the roof. It seemed to gum up when I was tinkering and burning much less smoke and just after the fan kicked on but before burning the smoke. I would also move my water level indicator. It is a high temp silicon tube in a nice, easy to see spot but got dirty from smoke out the door pretty quick, you need to wipe it off to see the water level. And If starting over I would make the original gasification tube much larger for flow or have a second fan that could be controlled independently for maximum efficiency. The original one was certainly better than nothing but it was improved greatly after modification. The baffle plates seem to work good, I would maybe extend them a little bit lower on the outside edges. But that would take away some firebox space.

I’m going to try and get a video of the secondary combustion. It sure is hard though with no viewing window!

I hope this might be helpful to someone planning a build or wanting to modify theirs!

In Liberty

Ben

8

Home Made / Re: Higher efficiency conventional build scotch type

« on: November 10, 2015, 12:17:30 PM »

Thanks for the comments!

Well I couldn't handle it anymore, I was to excited to turn off my water heater. I fired the boiler up Saturday morning. Its been running 4 days. It hasn't been all that cold, just below freezing at night but up to 5-10 C during the day. The boiler has been doing a lot of idling. I'm running at 185 5deg differential. It will overshoot and stop at about 188-189. The longest idle time would be around 8-9 hrs (estimate). So I'm hardly burning any wood. It smokes a little when it starts after a long idle until the firebox warms up (maybe 2 minutes to a roaring fire).

I didn't weigh any wood yet but I did put my thermocouple temporarily in the firebox up by the secondary air tube. When the burn cycle starts the temp at the top of the firebox climbs, the smoke stays until it hits about 8-900 degrees F. After that the temperature by the firebox baffles quickly climbs and hovers around 1250 degrees. It started raining after this pic was taken so I took the camera in but the highest peak temp I recorded was 1375 F. I'm quite pleased with that. That should be doing a fair bit of secondary combustion.

A quick link some may find informative:

http://www.uky.edu/bae/sites/www.uky.edu.bae/files/AEES-36_0.PDF

electrical box with PWM speed control added

new forced air, air intake with filter. I was worried about snow drifting in.

On a side note, I got a new to me toy and I've been using it for pretty much everything.

Removing front door system to install a new tighter one.

I do intend on weighing some wood and calculating efficiency. And will keep everyone posted when it actually gets cold and I convert some wood to btu's!

edit: I forgot, It took the water from 53 degrees up to 189 in an hour and a half. So 1751lbs x 136 deg = 238,136 btu (not counting steel) / 1.5hr = 158,757 btu/hr

It doesn't seem to burn as efficient when warming up initially until the water reaches about 165 degrees. I will time a cycle when I up my differential.

In Liberty

Ben

Well I couldn't handle it anymore, I was to excited to turn off my water heater. I fired the boiler up Saturday morning. Its been running 4 days. It hasn't been all that cold, just below freezing at night but up to 5-10 C during the day. The boiler has been doing a lot of idling. I'm running at 185 5deg differential. It will overshoot and stop at about 188-189. The longest idle time would be around 8-9 hrs (estimate). So I'm hardly burning any wood. It smokes a little when it starts after a long idle until the firebox warms up (maybe 2 minutes to a roaring fire).

I didn't weigh any wood yet but I did put my thermocouple temporarily in the firebox up by the secondary air tube. When the burn cycle starts the temp at the top of the firebox climbs, the smoke stays until it hits about 8-900 degrees F. After that the temperature by the firebox baffles quickly climbs and hovers around 1250 degrees. It started raining after this pic was taken so I took the camera in but the highest peak temp I recorded was 1375 F. I'm quite pleased with that. That should be doing a fair bit of secondary combustion.

A quick link some may find informative:

http://www.uky.edu/bae/sites/www.uky.edu.bae/files/AEES-36_0.PDF

electrical box with PWM speed control added

new forced air, air intake with filter. I was worried about snow drifting in.

On a side note, I got a new to me toy and I've been using it for pretty much everything.

Removing front door system to install a new tighter one.

I do intend on weighing some wood and calculating efficiency. And will keep everyone posted when it actually gets cold and I convert some wood to btu's!

edit: I forgot, It took the water from 53 degrees up to 189 in an hour and a half. So 1751lbs x 136 deg = 238,136 btu (not counting steel) / 1.5hr = 158,757 btu/hr

It doesn't seem to burn as efficient when warming up initially until the water reaches about 165 degrees. I will time a cycle when I up my differential.

In Liberty

Ben

9

Equipment / Re: moisture meter

« on: October 29, 2015, 01:00:45 PM »

I got this one:

http://www.amazon.ca/Neewer-Digital-Moisture-Humidity-Tester/dp/B007M86KSO/ref=sr_1_18?ie=UTF8&qid=1446145166&sr=8-18&keywords=moisture+meter

I heard the four prong ones are better. Plus is uses a 9v battery and not those tiny little ones.

Seems to work fine.

In Liberty

Ben

http://www.amazon.ca/Neewer-Digital-Moisture-Humidity-Tester/dp/B007M86KSO/ref=sr_1_18?ie=UTF8&qid=1446145166&sr=8-18&keywords=moisture+meter

I heard the four prong ones are better. Plus is uses a 9v battery and not those tiny little ones.

Seems to work fine.

In Liberty

Ben

11

Home Made / Re: Higher efficiency conventional build scotch type

« on: August 06, 2015, 11:31:42 AM »

Another update. Sorry about the frequent updates, Its a little dead on the forum in the summer but I have to post what happened or I will forget the numbers.

The temperature outside went down to 21 C or so last weekend so I had her maiden burn. Just a small fire to get it up to temp and make sure everything is fine.

I loaded 1/2-3/4 of a wheelbarrow of sawmill scraps and about 6 5" pcs about 2' long of poplar and a few pieces of ash. I didn't weigh it, also I'm waiting for my new moister tester. The fire lit easily with the under-fire air. The 210 gal of water went from 77 deg to 190 deg in 1 3/4 hours. The firebox was certainly not full.

1751 Lbs x 113 deg = 197,908 btu

197,908/ 1.75 = 113,090 btu/hr

It drew a surprising draft for naturally aspirated. The probe in the chimney registered on average between 105-115 deg F above water temp ex- water at 160 chimney at 270, water at 175 chimney at 290.

The highest the flue temp recorded was 305.

There was a fair amount of condensation dripping from the ash door on start-up and until the temp reached about 120. The boiler cycled on and off a few times that evening until the wood was gone. There was a very thin black film on the side walls of the firebox and heat exchanger tubes. This seems to have dried up when the temp hit about 175.

The initial run went better than expected but about what I hoped. I have a PWM dc motor speed control on the way so then I can add my blower fan and I also ordered a thermocouple for the firebox. This should let me know the water temp, flue temp and firebox temp. I wired an empty beer can right up to the gasification tube to see if it would make it over 1200 deg there. It didn't melt and drip off but the corners did seem melted. It was drooped down about 1 1/2 times as long as when it went in. So that makes me happy that we are seeing fairly high temps up there in the firebox.

I left my pump run until the water was cold, We used "free" hot water for about 3 days after the fire died!

When it gets colder in the fall I will do a complete test... and report!

In Liberty

Ben

The temperature outside went down to 21 C or so last weekend so I had her maiden burn. Just a small fire to get it up to temp and make sure everything is fine.

I loaded 1/2-3/4 of a wheelbarrow of sawmill scraps and about 6 5" pcs about 2' long of poplar and a few pieces of ash. I didn't weigh it, also I'm waiting for my new moister tester. The fire lit easily with the under-fire air. The 210 gal of water went from 77 deg to 190 deg in 1 3/4 hours. The firebox was certainly not full.

1751 Lbs x 113 deg = 197,908 btu

197,908/ 1.75 = 113,090 btu/hr

It drew a surprising draft for naturally aspirated. The probe in the chimney registered on average between 105-115 deg F above water temp ex- water at 160 chimney at 270, water at 175 chimney at 290.

The highest the flue temp recorded was 305.

There was a fair amount of condensation dripping from the ash door on start-up and until the temp reached about 120. The boiler cycled on and off a few times that evening until the wood was gone. There was a very thin black film on the side walls of the firebox and heat exchanger tubes. This seems to have dried up when the temp hit about 175.

The initial run went better than expected but about what I hoped. I have a PWM dc motor speed control on the way so then I can add my blower fan and I also ordered a thermocouple for the firebox. This should let me know the water temp, flue temp and firebox temp. I wired an empty beer can right up to the gasification tube to see if it would make it over 1200 deg there. It didn't melt and drip off but the corners did seem melted. It was drooped down about 1 1/2 times as long as when it went in. So that makes me happy that we are seeing fairly high temps up there in the firebox.

I left my pump run until the water was cold, We used "free" hot water for about 3 days after the fire died!

When it gets colder in the fall I will do a complete test... and report!

In Liberty

Ben

12

Home Made / Re: Higher efficiency conventional build scotch type

« on: July 31, 2015, 07:02:31 AM »

Another update! So she is home and installed. I haven't sparked it up yet, its been very hot outside. So another update is to follow.

So it is hooked up to heat the garage and the house. The boiler is 30 feet from the garage and then about another 20 from there to the house basement. The logstor is installed in a 6" drain tile and comes up through the wall of the garage above the sill plate. The garage is a floating slab and the outer perimeter is 20" of concrete. So I wasn't going to drill two holes in it. The logstor goes as the crow flies to the corner of the garage (closest to the house) then over to the house. My pump is in the garage, there is a zone valve and small air/water hx there to keep the snow off the car. In the basement there is only a water/air hx in the plenum and a 30 plate hx for the domestic hot water. I really tried to keep the pipe length and fittings to a minimum. I ended up using about 88 feet of logstor.

I added my extra length of chimney when I got it home and the rain cap/spark arrestor (required by insurance). The insurance guy actually really liked it and doesn't require any extra fee's for homemade. I have include a finished pic with the firebrick and baffle plates. I was fairly close with my calculation of water capacity. I got a flow meter for the hose and put 210 gal of water in. I can get another 10 or so but I'm not sure how much expansion room I need until I get up to temp for the first time. I put rust inhibitor in ( I got from an industrial boiler supply place) and sent them a water sample. I wonder how accurate water capacity claims are on the factory made boilers. I wanted and accurate measurement for calculating efficiency when its going.

I am happy with this taco bumblebee pump except its flow display is not accurate at all. It seems to measure the rpm of the pump to calculate flow. But even if you partially close the isolation valve the flow display barely changes. The impellor still obviously turns and there is little to no flow. Just a note to someone considering this pump.

I had to move a couple apple trees to put the boiler here. The little one is looking good. The big one barely has any leaves except maybe 2 branches. We will see how they fare. Also it sure is hard to get grass to grow with free range chickens. Every day I get home they are gobbling up seed...

gallery link http://s1300.photobucket.com/user/benamyeby/library/boiler?sort=3&page=1

In Liberty!

Ben

So it is hooked up to heat the garage and the house. The boiler is 30 feet from the garage and then about another 20 from there to the house basement. The logstor is installed in a 6" drain tile and comes up through the wall of the garage above the sill plate. The garage is a floating slab and the outer perimeter is 20" of concrete. So I wasn't going to drill two holes in it. The logstor goes as the crow flies to the corner of the garage (closest to the house) then over to the house. My pump is in the garage, there is a zone valve and small air/water hx there to keep the snow off the car. In the basement there is only a water/air hx in the plenum and a 30 plate hx for the domestic hot water. I really tried to keep the pipe length and fittings to a minimum. I ended up using about 88 feet of logstor.

I added my extra length of chimney when I got it home and the rain cap/spark arrestor (required by insurance). The insurance guy actually really liked it and doesn't require any extra fee's for homemade. I have include a finished pic with the firebrick and baffle plates. I was fairly close with my calculation of water capacity. I got a flow meter for the hose and put 210 gal of water in. I can get another 10 or so but I'm not sure how much expansion room I need until I get up to temp for the first time. I put rust inhibitor in ( I got from an industrial boiler supply place) and sent them a water sample. I wonder how accurate water capacity claims are on the factory made boilers. I wanted and accurate measurement for calculating efficiency when its going.

I am happy with this taco bumblebee pump except its flow display is not accurate at all. It seems to measure the rpm of the pump to calculate flow. But even if you partially close the isolation valve the flow display barely changes. The impellor still obviously turns and there is little to no flow. Just a note to someone considering this pump.

I had to move a couple apple trees to put the boiler here. The little one is looking good. The big one barely has any leaves except maybe 2 branches. We will see how they fare. Also it sure is hard to get grass to grow with free range chickens. Every day I get home they are gobbling up seed...

gallery link http://s1300.photobucket.com/user/benamyeby/library/boiler?sort=3&page=1

In Liberty!

Ben

13

Home Made / Re: Higher efficiency conventional build scotch type

« on: April 20, 2015, 06:44:46 AM »

I've updated the gallery for probably the last time until I get a pad poured to install. That won't probably be till july or so... We will see how busy the summer is. I haven't finished the outside ash cleanout door. I have to line it with matching steel. It's just white now. I also have to do the wiring in the outside box for the aquastat. The picture of the damper actuator was just for testing. I wound up going a little overkill on the insulation if there is such a thing. The sides, bottom and top are R44 and the front and back is r28. Should be good enough. I have to add weather stripping to the outside door also.

Here is the gallery

http://s1300.photobucket.com/user/benamyeby/library/boiler?sort=3&page=1

One attached here:

In Liberty

Ben

Here is the gallery

http://s1300.photobucket.com/user/benamyeby/library/boiler?sort=3&page=1

One attached here:

In Liberty

Ben

14

Home Made / Re: Higher efficiency conventional build scotch type

« on: March 24, 2015, 01:06:43 PM »

slimjim, Thanks for the comment!

First, it's amazing how many people pay lip service to things like freedom and liberty but have no Idea what they are....

Second, I appreciate the concern about the creosote. I have thought about this a while and only time will tell what happens. I do have a backup plan for a bypass if this thing turns out to be a turd. I roughly measured out the total heating area of my tubes and its not much different than the P&M. The cross sectional area of the tubes is about 15% larger than the 6" flue. I didn't want things to keep getting bigger as when gasses expand they cool. I am putting a probe in the stack and am hoping for 280-300 deg temps. I have purposely made it easy to wirebrush the tubes from the front so I can keep an eye on them. I am also hoping the interior firebox design will permit higher burn temps which hopefully burns more of that nasty creosote. I'm planning on large curved baffles on either side of the gasification tube to hold the heat in there (not it contact with the water jacket). Also with no water in the floor and brick down there, I don't think those things will hurt my chances.

I would really like if I could use both passes of tubes, it seems like a waste having 4-600 deg stack temps.

In liberty

Ben

First, it's amazing how many people pay lip service to things like freedom and liberty but have no Idea what they are....

Second, I appreciate the concern about the creosote. I have thought about this a while and only time will tell what happens. I do have a backup plan for a bypass if this thing turns out to be a turd. I roughly measured out the total heating area of my tubes and its not much different than the P&M. The cross sectional area of the tubes is about 15% larger than the 6" flue. I didn't want things to keep getting bigger as when gasses expand they cool. I am putting a probe in the stack and am hoping for 280-300 deg temps. I have purposely made it easy to wirebrush the tubes from the front so I can keep an eye on them. I am also hoping the interior firebox design will permit higher burn temps which hopefully burns more of that nasty creosote. I'm planning on large curved baffles on either side of the gasification tube to hold the heat in there (not it contact with the water jacket). Also with no water in the floor and brick down there, I don't think those things will hurt my chances.

I would really like if I could use both passes of tubes, it seems like a waste having 4-600 deg stack temps.

In liberty

Ben

15

Home Made / Re: Higher efficiency conventional build scotch type

« on: March 24, 2015, 11:52:54 AM »

Added a couple pictures to the gallery. I have some of the latch, the hinges, the door insulation and basket. I have 3" of ceramic insulation in the door and 1" in the first cleanout box. In the chimney cleanout there is an angled stainless heat shield to deflect the flue gasses up the chimney. It just leans in there so I can take it out if it doesn't do anything.

In Liberty

Ben

In Liberty

Ben

Pages: [1] 2