Welcome, Guest. Please login or register.

Did you miss your activation email?

Show Posts

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

61

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 26, 2016, 04:07:02 PM »

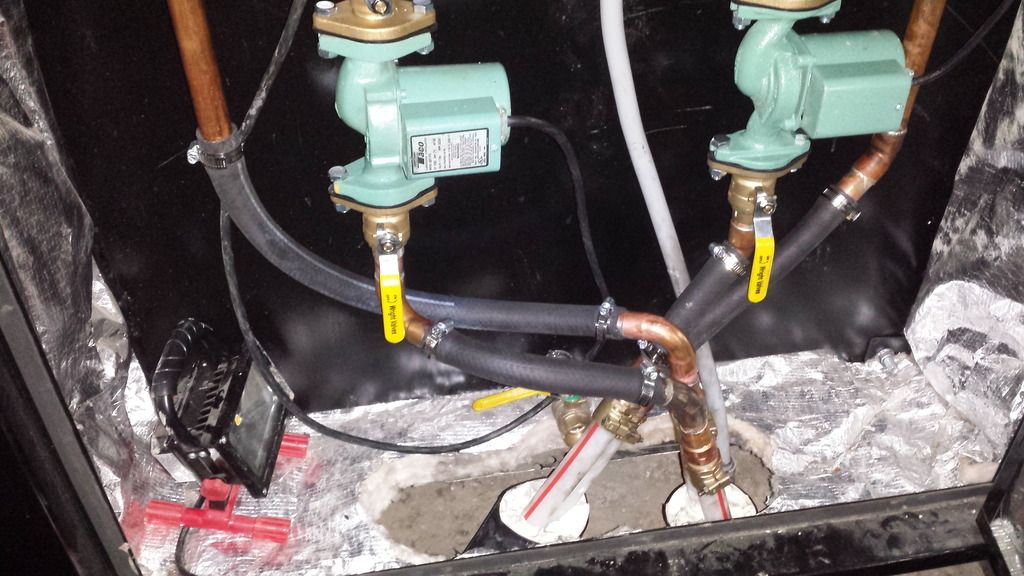

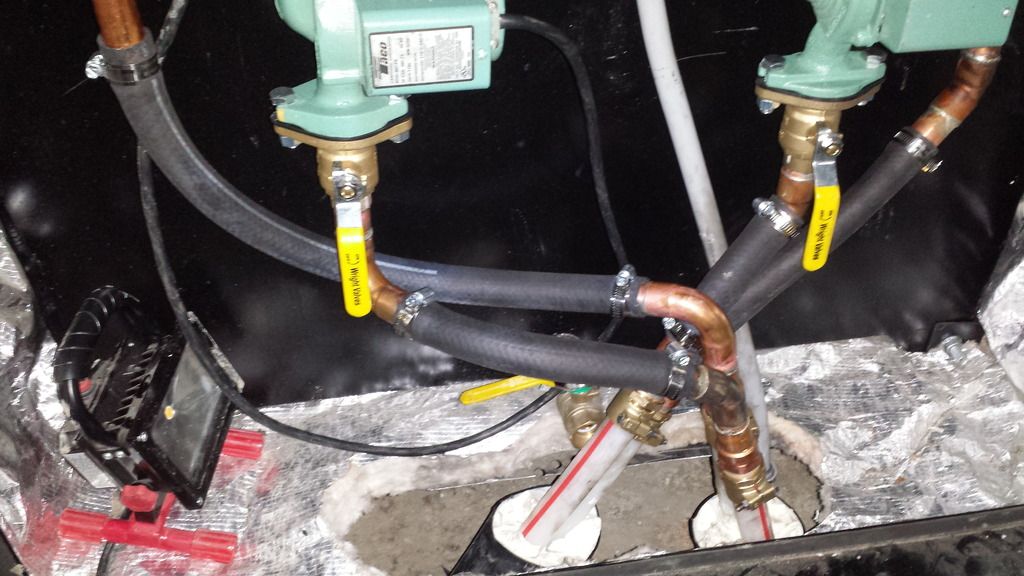

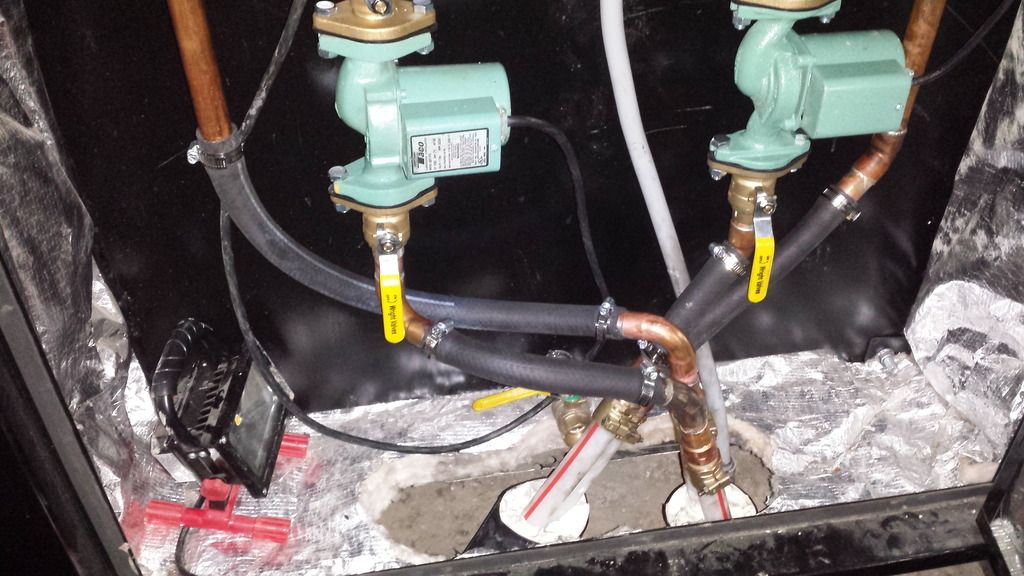

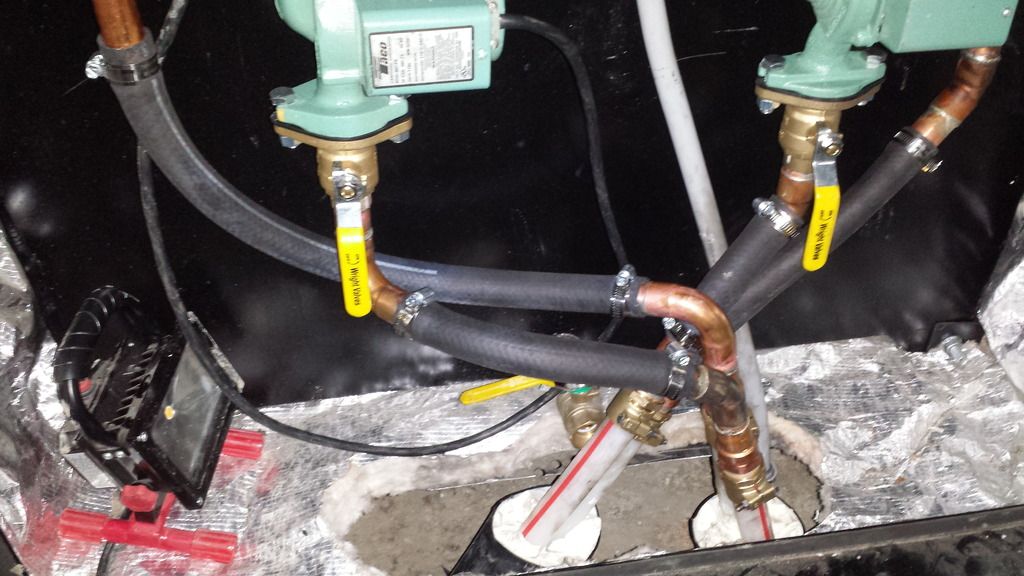

Boiler is filled and plumbing is connected to the oil boiler system. That side of it is only for this year hopefully as I hope to replumb the hydronic system to a primary secondary system next spring. Foam insulation behind the heat exchanger, gauges on in and out of the hx for both systems and return temp gauges on the back of the g200. Probably will give it a day to circulate then I'll pull a water sample for testing and light a fire.

One of the copper unions was leaking, one heater hose clamp I forgot to tighten, and 1 joint had to be re-soldered. That's the extent of the issues I've had so far. Really trouble free install overall. Can't wait to fire it up and see how it runs.

One of the copper unions was leaking, one heater hose clamp I forgot to tighten, and 1 joint had to be re-soldered. That's the extent of the issues I've had so far. Really trouble free install overall. Can't wait to fire it up and see how it runs.

62

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 25, 2016, 08:51:11 PM »

It will have a spacer behind it to provide insulation from the concrete. Everything in that spot is tight clearances so I wasn't sure how much space I was going to have. I should have enough room to space it out with some insulation. Other than that the boiler side is now ready to fill tomorrow morning while I work on connecting the heat exchanger to the oil boiler.

64

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 24, 2016, 07:37:14 PM »Are you going to put temp gauges on your supply and return? 007 pump Max's out at 10 feet of head. As long as your return temps to your boiler are less than 20 delta t you are fine.

I'll have them on the return to the boiler and at both feed and return at the heat exchanger in the basement

66

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 24, 2016, 04:27:33 PM »What size tacos did you use?

I had 2 007 F5 circ pumps from the stuff from my friend, I have several other pumps to choose from if these don't work out well, but these are the only tacos. I have almost no elevation change from the boiler to the house with only about a 50' run of logstor. In the house there are only 4 long sweep 90's each way from the heat exchanger. Should be plenty of flow from the 007 as there's very low head pressure. All of the valves and shutoff flanges are full port as well.

I'm also planning on 4 gauges near the heat exchanger so I can measure the heat transfer, I put the ones on the boiler so I can see the total system heat drop and monitor the boiler return water temps.

67

General Outdoor Furnace Discussion / Re: Happy Thanksgiving!

« on: November 24, 2016, 05:59:12 AM »

Happy Thanksgiving to everyone!

68

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 23, 2016, 08:10:31 PM »

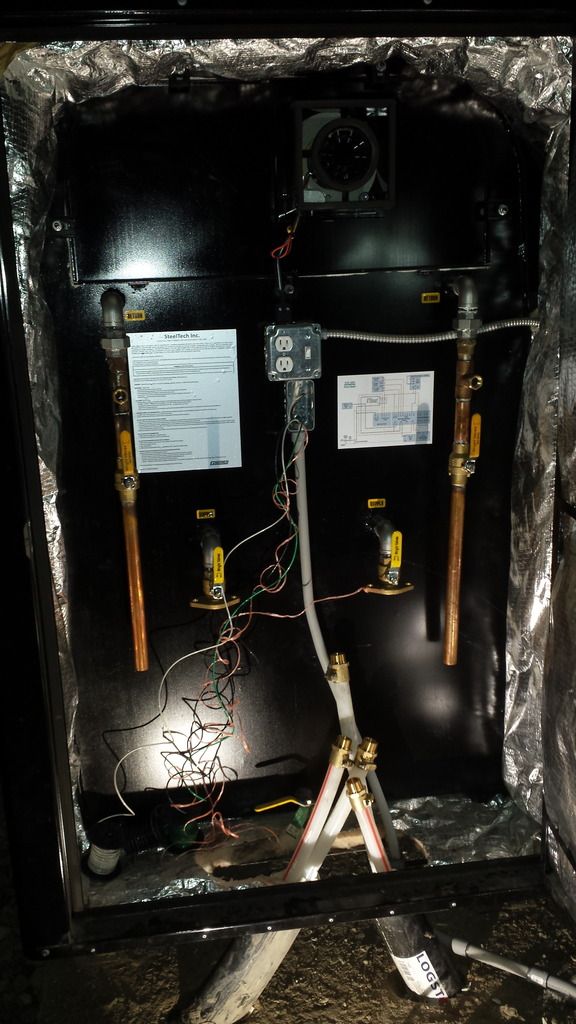

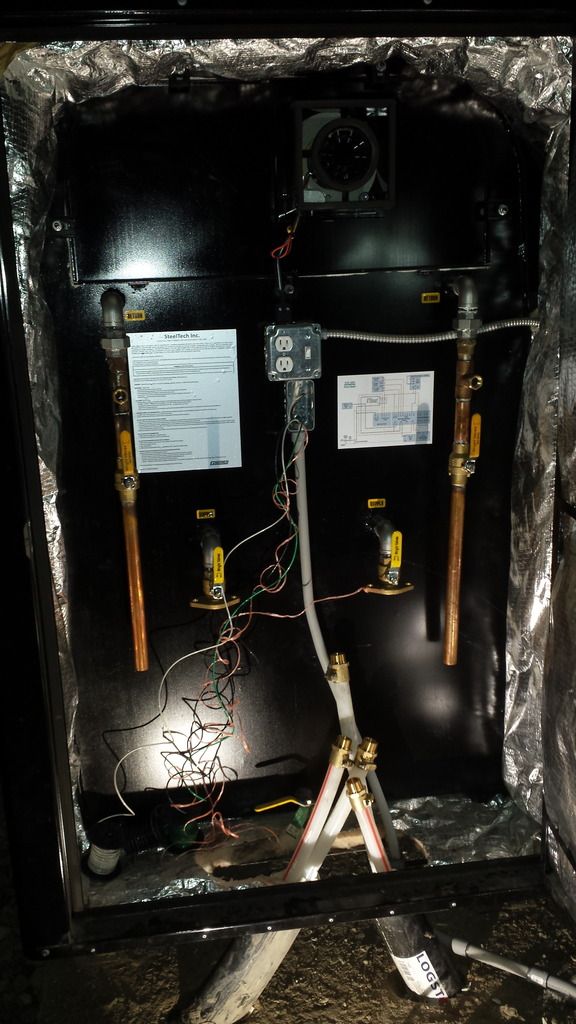

Got the back of the boiler plumbing done tonight. I also got a temp loop in the barn of heater hose looped from the supply to the return pex, but not really anything there worthy of a picture. Forgot to get some fittings for installing the basement plumbing and bought a couple of things that were not what I actually need, so I'll have to pick up the rest of what I need on Friday. Happy Thanksgiving to anyone reading this thread!

House circuit

Barn circuit

House circuit

Barn circuit

69

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 21, 2016, 09:37:22 PM »

Spent a couple hours tonight after putting the kids to bed working on plumbing and running power to the boiler

Got the basement end of the pipe cut back and the adapter fittings installed. I am actually surprised how small the inner diameter of the fittings is, it almost looks like the equivalent of 3/4" copper.

Bought some 1 1/4" copper unions and adapters. Gotta love how expensive it is. Going to run the unions to the threaded heat exchanger ports then run 1 1/4" tee's that have 3/4" nptf for hose bibs to allow draining/purging/cleaning then adapt down to 1" ball valves and long sweep 90's to the connections from the underground pipe. Should flow really well without having to use any bullnose tees.

The threaded ports will get temp gauges so I can tell what the return water temperature is. Full port 1" ball valves and full port shutoff flanges for the circulation pumps. All copper or stainless fittings

Got the basement end of the pipe cut back and the adapter fittings installed. I am actually surprised how small the inner diameter of the fittings is, it almost looks like the equivalent of 3/4" copper.

Bought some 1 1/4" copper unions and adapters. Gotta love how expensive it is. Going to run the unions to the threaded heat exchanger ports then run 1 1/4" tee's that have 3/4" nptf for hose bibs to allow draining/purging/cleaning then adapt down to 1" ball valves and long sweep 90's to the connections from the underground pipe. Should flow really well without having to use any bullnose tees.

The threaded ports will get temp gauges so I can tell what the return water temperature is. Full port 1" ball valves and full port shutoff flanges for the circulation pumps. All copper or stainless fittings

71

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 19, 2016, 02:39:04 PM »

Was supposed to be delivered today, but Richard was delayed at a job in VT. Hopefully it'll be delivered tomorrow. Spent 4 hours pulling copper pipe and plumbing parts from a friend's basement. He switched from hydronic oil to natural gas monitor heaters. Gave me anything I wanted to take. 5 circ pumps, 6 zone controller, misc fittings/valves and tons of 3/4 and 1" copper pipe. I left a bit more 1" and lots of 3/4". I can always go get it later. The system has been off for a couple of years and it was never drained, so most of the time I was there was simply draining the system. Large 3 unit building, probably somewhere around 100 gal in the heating system.

74

HeatMaster / Re: New G200 replacing a rusted out Shaver

« on: November 11, 2016, 04:54:44 AM »Nice pics, does this new development mean that you will also be changing your screen name as well.

The screen name is based on my side job. Frozen Mongrel Fabrication. I modify vehicles, usually for off road use, but I've done several street vehicles as well. I've been doing it for several years and chose the name a few years ago.

75

HeatMaster / New G200 replacing a rusted out Shaver

« on: November 10, 2016, 07:31:11 PM »

So I finally got around to starting a thread to document my G200 install. I've been working with Slimjim since I put a deposit on a G200 at the Fryeburg fair this year. So far I've gotten the old boiler removed and today he dropped off the new Logstor pipe for the runs to the house and barn. The old stuff was simply pex wrapped in black foam insulation like you can get at any hardware store then stuck through 4" PVC pipe. The pipe was never sealed so there was a lot of ground water that got into it. Last year was the 1st year I owned this house and without heating the barn I went through over 9 cords of wood. Lots of it was pine as I didn't have much time before winter when I moved into the house. Melted a good portion of the snow where the underground lines were.

The house came with an old Shaver boiler and this summer I knew that I was going to have an issue with is as all of the water leaked out of it at some point. Unfortunately I didn't catch it until later in the summer as I work tons of hours and have side jobs that fill up pretty much all my free time. Once I started looking into it I discovered that the entire bottom of the Shaver was rusted through like Swiss cheese. I do metal fabrication work and welding, so I was very tempted to just fix it until I figured out that the entire water jacket would pretty much have to be rebuilt. All that effort and time for a very inefficient boiler really didn't make sense and so that's what started me looking at the alternatives. Selected a G200 after doing lots of research. I live about 10 min away from Slimjim, so it made the choice even easier. I removed the old boiler and dug the lines out last Saturday and today Slimjim came over with the bus and trailer to get me the Logstor pipe I needed. The old concrete pad from the Shaver had a couple of 5" diameter holes that the PVC had been fed through and I was able to get the Logstor fed through those and into the barn and basement of the house. Here are a few pictures of the old boiler and then of the trench and new Logstor pipe. My property has an extremely high water table, so when I was digging the trench I actually ran into ground water less than 2' down. I tried pumping it out and had drained it almost completely last night, but today when I was running the Logstor there was almost 2' of water in the bottom of the trenches.

This is an overview of the old system after I had started taking it apart to inspect for leaks

The old plumbing coming into the walk out basement and connecting to a water to water HX

Starting digging out the old pipes and trenching for the Logstor

You can see how high the water is in the trench. I was watching it flow in from the sides of the trenches as I was digging it. Not much I can do about it and with the Logstor it shouldn't be an issue

Cut the old water jacket off the Shaver with my plasma cutter to see how bad the sludge buildup really was. There was about 5" of sludge in the bottom and numerous places that it had rusted through.

The new Logstor pipe

short run into the barn

both runs fed through the existing holes in the concrete pad

Can't really see it, but the logstor is starting to be back filled here

Barn end of the logstor. This will eventually get connected to a retrofitted mobile home furnace for heat.

Plenty of Logstor run into the house to plumb into the hydronic system

The house came with an old Shaver boiler and this summer I knew that I was going to have an issue with is as all of the water leaked out of it at some point. Unfortunately I didn't catch it until later in the summer as I work tons of hours and have side jobs that fill up pretty much all my free time. Once I started looking into it I discovered that the entire bottom of the Shaver was rusted through like Swiss cheese. I do metal fabrication work and welding, so I was very tempted to just fix it until I figured out that the entire water jacket would pretty much have to be rebuilt. All that effort and time for a very inefficient boiler really didn't make sense and so that's what started me looking at the alternatives. Selected a G200 after doing lots of research. I live about 10 min away from Slimjim, so it made the choice even easier. I removed the old boiler and dug the lines out last Saturday and today Slimjim came over with the bus and trailer to get me the Logstor pipe I needed. The old concrete pad from the Shaver had a couple of 5" diameter holes that the PVC had been fed through and I was able to get the Logstor fed through those and into the barn and basement of the house. Here are a few pictures of the old boiler and then of the trench and new Logstor pipe. My property has an extremely high water table, so when I was digging the trench I actually ran into ground water less than 2' down. I tried pumping it out and had drained it almost completely last night, but today when I was running the Logstor there was almost 2' of water in the bottom of the trenches.

This is an overview of the old system after I had started taking it apart to inspect for leaks

The old plumbing coming into the walk out basement and connecting to a water to water HX

Starting digging out the old pipes and trenching for the Logstor

You can see how high the water is in the trench. I was watching it flow in from the sides of the trenches as I was digging it. Not much I can do about it and with the Logstor it shouldn't be an issue

Cut the old water jacket off the Shaver with my plasma cutter to see how bad the sludge buildup really was. There was about 5" of sludge in the bottom and numerous places that it had rusted through.

The new Logstor pipe

short run into the barn

both runs fed through the existing holes in the concrete pad

Can't really see it, but the logstor is starting to be back filled here

Barn end of the logstor. This will eventually get connected to a retrofitted mobile home furnace for heat.

Plenty of Logstor run into the house to plumb into the hydronic system

Lots of plumbing to do now, but it feels good to have it in place.

Lots of plumbing to do now, but it feels good to have it in place.